Informations

The artificial marble industry is a rapidly growing sector that utilizes advanced technologies to produce beautiful and durable marble-like products. However, the production process is complex and requires high-quality molds to maintain consistency and accuracy. These molds are often made from rubber and require regular protection to maintain their integrity and extend their lifespan. Water soluble films have emerged as an effective solution for rubber mold protection in the artificial marble industry.

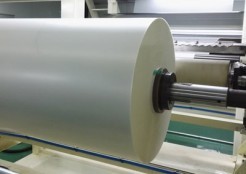

Water soluble films are thin, flexible sheets of plastic that dissolve when exposed to water. They have been widely used in various industries, including the artificial marble industry, for a range of applications. The primary advantage of using water soluble films for rubber mold protection is their ease of application. These films can be easily wrapped around the mold, providing a protective barrier that prevents damage and extends the lifespan of the mold.

In the artificial marble industry, water soluble films are used during the production process. The film is applied to the rubber mold, ensuring that all areas are properly covered. This provides a protective layer that can prevent damage during production, transportation, and storage. By using water soluble films, manufacturers can reduce the frequency of mold replacements, resulting in cost savings and increased productivity.

Another advantage of using water soluble films for rubber mold protection in the artificial marble industry is their environmental friendliness. These films are made from biodegradable materials that can be easily disposed of without causing harm to the environment. This is particularly important in the artificial marble industry, where environmental sustainability is a top priority.

Despite their many advantages, there are some challenges associated with using water soluble films in the artificial marble industry. One of the main challenges is ensuring proper adherence of the film to the rubber mold. If the film does not adhere properly, it may not provide sufficient protection or may even peel off during use. To address this issue, manufacturers can use adhesives or specialized primers to enhance the adherence of the film to the rubber mold.

Another challenge is maintaining the structural integrity of the film during production and processing. The film may experience stretching or tearing when subjected to high temperatures and pressures during production. To overcome this challenge, manufacturers can use thicker films or select materials with higher tensile strength to enhance the structural integrity of the film.

Despite these challenges, water soluble films remain a highly effective solution for rubber mold protection in the artificial marble industry. By addressing these challenges through careful material selection and application techniques, manufacturers can take advantage of the many benefits offered by these films, including cost savings, increased productivity, and environmental sustainability.

In conclusion, water soluble films have emerged as a crucial tool for rubber mold protection in the artificial marble industry. By effectively protecting molds from damage and extending their lifespan, these films can contribute significantly to cost savings and increased productivity while maintaining environmental sustainability. As the artificial marble industry continues to grow and advance, it is likely that water soluble films will play an increasingly important role in its success.