Informations

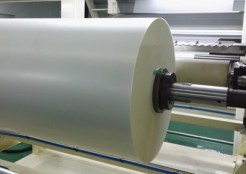

PVA water-soluble film has gained

widespread popularity as a sustainable and eco-friendly alternative to

traditional packaging materials. One of the industries that have recently

adopted this innovative packaging solution is the fiberglass industry. In this

essay, we will explore how PVA water-soluble film can be used in fiberglass

packaging and provide a comprehensive guide on how to use it effectively.

Fiberglass is a composite material made

from a combination of glass fibers and resin. During the manufacturing process,

the fiberglass is molded into various shapes using molds. One critical aspect

of this process is the application of a release agent to the mold surface,

which ensures that the fiberglass product does not stick to the mold.

PVA water-soluble film is an excellent

release agent for fiberglass packaging. Its water-solubility and low toxicity

make it an ideal material for mold preparation. The film is dissolved in water

and applied to the mold surface using a sprayer, roller, or brush, ensuring

that the fiberglass product can be removed easily without damaging the mold.

To use PVA water-soluble film in fiberglass

packaging, follow these steps:

1-Prepare the mold surface: The mold surface

should be clean, dry, and free from any debris. It's recommended to use a mold

cleaner to ensure the surface is completely clean.

2-Dilute the PVA water-soluble film: PVA

water-soluble film is supplied in a concentrated form and needs to be diluted with

water. Follow the manufacturer's instructions for the correct dilution ratio.

3-Apply the PVA water-soluble film: Apply the

diluted PVA water-soluble film to the mold surface using a sprayer, roller, or

brush. Ensure that the film is evenly applied, and there are no areas left

uncoated.

4-Allow the film to dry: The PVA

water-soluble film will dry quickly, usually within 10-20 minutes.

5-Apply the fiberglass: Once the PVA

water-soluble film is dry, the fiberglass can be applied to the mold surface.

6-Remove the fiberglass product: Once the

fiberglass has cured, the product can be removed from the mold surface easily

without damaging the mold.

Using PVA water-soluble film in fiberglass

packaging offers several benefits. It is environmentally friendly, non-toxic, and

easy to use. It also provides an excellent release agent, ensuring that the

fiberglass product can be removed from the mold without any damage or sticking.

In conclusion, PVA water-soluble film is a

sustainable and effective solution for fiberglass packaging. By following the

steps outlined in this essay, you can effectively use PVA water-soluble film in

your fiberglass manufacturing process, while reaping the benefits of its

eco-friendliness and ease of use.