Informations

Artificial marble, also known as engineered

marble, is a popular material in the construction industry due to its aesthetic

appeal, durability, and ease of maintenance. The production process of

artificial marble involves the use of molds that require effective release

agents for a smooth surface finish. In this essay, we will discuss the working

process of PVA water-soluble film for mold release during the production of

artificial marble.

Working Process of PVA Water Soluble Film

for Mold Release:

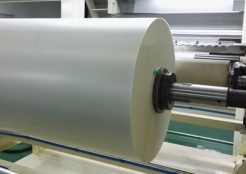

PVA water-soluble film is a type of polymer

film that dissolves quickly in water, leaving behind a clean and smooth

surface. The use of PVA water-soluble film for mold release in artificial

marble production involves the following steps:

Step 1: Mold Preparation

The mold is cleaned thoroughly to remove

any dirt or debris that may interfere with the film's adhesion.

Step 2: Cutting and Placing the Film

The PVA water-soluble film is cut to the

shape and size of the mold and placed over the mold's surface. The film should

fit the mold snugly to prevent any gaps or wrinkles.

Step 3: Pouring the Artificial Marble

Mixture

The artificial marble mixture is then

poured into the mold. The PVA water-soluble film acts as a barrier between the

mold and the mixture, preventing the artificial marble from sticking to the

mold during the production process.

Step 4: Curing

The artificial marble is left to cure,

allowing the mixture to solidify and take the shape of the mold.

Step 5: Removing the Film

Once the artificial marble has cured, the

PVA water-soluble film can be easily removed by washing the mold with water.

The film dissolves quickly in water, leaving behind a clean and smooth surface.

In conclusion, PVA water-soluble film is a

crucial component in the production of artificial marble. Its use as a mold

release agent ensures a smooth surface finish, prevents sticking to the mold,

and is environmentally friendly. The working process of PVA water-soluble film

for mold release during the production of artificial marble involves mold

preparation, cutting and placing the film, pouring the artificial marble

mixture, curing, and removing the film. This process is simple and effective,

resulting in high-quality and aesthetically appealing artificial marble.