Informations

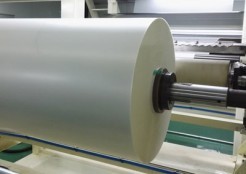

Polycarbonate panels are a popular choice

for building materials due to their durability, light weight, and ease of

installation. However, during the transportation, handling, and installation

processes, these panels are at risk of being scratched, scuffed, or damaged. To

prevent this, a temporary protective film is essential for ensuring that the

panels remain in pristine condition. In this essay, we will discuss the reasons

why polycarbonate panels need a temporary protective film and how it can

benefit construction projects.

One of the primary reasons for using a

temporary protective film for polycarbonate panels is to prevent scratches and

scuffs. During transportation and handling, panels are exposed to various

hazards that can cause damage to the surface. For example, dust, debris, and

other contaminants can scratch the surface of the panel. A temporary protective

film provides a barrier between the panel and these contaminants, preventing

scratches and scuffs from occurring.

Another reason why polycarbonate panels

require a protective film is to protect against UV damage. Polycarbonate panels

are prone to discoloration and damage due to exposure to UV rays from the sun.

A temporary protective film with UV inhibitors can prevent this damage and help

to maintain the original color and clarity of the panel.

In addition to protecting against physical

damage and UV exposure, a temporary protective film can also prevent adhesive

transfer. Adhesives used in the installation of polycarbonate panels can leave

residue on the surface of the panel, which can be difficult to remove and can

impact the aesthetic appeal of the panel. A protective film provides a barrier

between the adhesive and the panel, preventing any residue from transferring to

the surface.

Using a temporary protective film for

polycarbonate panels can benefit construction projects in several ways. First,

it can help to reduce the costs associated with damaged panels. Scratched or

damaged panels may need to be replaced, which can be costly and time-consuming.

By using a protective film, construction teams can ensure that the panels

arrive at the job site in pristine condition, reducing the need for

replacements.

Another benefit of using a temporary

protective film is that it can help to improve the overall quality of the

finished project. Panels that are free from scratches and scuffs are more

aesthetically pleasing, and maintain their clarity and color for longer. This

can help to increase the value of the project and improve the satisfaction of

the client.

In conclusion, the use of a temporary

protective film for polycarbonate panels is essential for ensuring that they

remain in pristine condition during transportation, handling, and installation.

Protective films prevent scratches and scuffs, protect against UV damage, and

prevent adhesive transfer. Using a protective film can benefit construction

projects by reducing costs, improving the quality of the finished project, and

increasing client satisfaction.