Informations

Artificial marble, also known as engineered

marble, is a popular material in the construction industry due to its aesthetic

appeal, durability, and ease of maintenance. The production process of

artificial marble involves the use of molds that require effective release

agents for a smooth surface finish. In this essay, we will discuss the

importance of PVA water-soluble film for mold release in the production of

artificial marble.

Why Use PVA Water Soluble Film for Mold

Release in Artificial Marble Production?

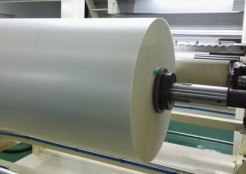

PVA water-soluble film is a type of polymer

film that dissolves quickly in water, leaving behind a clean and smooth

surface. This film is commonly used as a mold release agent in various

industries, including the production of artificial marble.

The use of PVA water-soluble film in

artificial marble production offers several advantages. Firstly, it provides an

effective release agent for the mold, which ensures that the artificial marble

does not stick to the mold during the production process. This helps to

maintain the shape and quality of the finished product. Additionally, PVA

water-soluble film is environmentally friendly, as it does not leave any

residue or harmful chemicals that can harm the environment.

Another benefit of using PVA water-soluble

film in artificial marble production is that it improves the surface finish of

the final product. The film acts as a barrier between the artificial marble and

the mold, preventing any imperfections or roughness from appearing on the

surface of the finished product. This results in a smooth and polished surface,

which enhances the overall aesthetic appeal of the artificial marble.

Moreover, PVA water-soluble film is easy to

apply and remove from the mold. It can be easily cut to fit the shape of the

mold, and it dissolves quickly in water, leaving no residue or trace of the

film on the artificial marble.

In conclusion, PVA water-soluble film is an

essential component in the production of artificial marble. Its use as a mold

release agent ensures a smooth surface finish, prevents sticking to the mold,

and is environmentally friendly. It is a cost-effective solution that enhances

the overall quality and aesthetic appeal of the artificial marble.