Informations

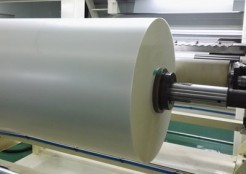

The chemical industry demands reliable and

effective packing solutions to ensure the safe transportation and storage of

various chemicals. One versatile option that has gained popularity in recent

years is PVA (Polyvinyl Alcohol) films. These films offer excellent protective

properties, making them ideal for packing applications in the chemical

industry. In this essay, we will explore the benefits of using PVA films for

packing in the chemical industry.

1- PVA films are known for their outstanding

moisture barrier properties, making them highly suitable for packing

moisture-sensitive chemicals. These films provide an effective barrier against

moisture, preventing the ingress of water or other liquids that can potentially

damage the chemicals. This helps in preserving the quality and integrity of the

chemicals during transportation and storage, reducing the risk of spoilage or

degradation.

2- In addition to their moisture barrier

properties, PVA films are also available in anti-static variants, making them

ideal for packing chemicals that are sensitive to static electricity. Static

electricity can pose a significant risk in the handling and transportation of

certain chemicals, as it can cause sparks and fires. Anti-static PVA films can

dissipate static charges, reducing the risk of static-related accidents and

ensuring safe packing and handling of chemicals.

3- PVA films are also versatile in terms of

their compatibility with various types of chemicals. They are chemically inert,

which means that they do not react with most chemicals, making them suitable

for packing a wide range of chemicals, including acids, bases, solvents, and

other hazardous substances. This versatility makes PVA films a reliable choice

for chemical packing solutions, providing a protective barrier that helps in

preserving the quality and safety of the chemicals.

4- Another advantage of PVA films is their

excellent clarity and transparency. This allows for easy visual inspection of

the packed chemicals, enabling quick identification and verification of the

contents. This can be particularly useful in the chemical industry, where

accuracy and traceability are critical.

5- Furthermore, PVA films can be easily

heat-sealed, providing a secure and tamper-evident packing solution. Heat-sealing

creates a tight seal, preventing the entry of contaminants and ensuring the

integrity of the packed chemicals. This helps in maintaining the quality and

safety of the chemicals during transportation and storage.

PVA films are a versatile

and reliable packing solution for the chemical industry. With their moisture

barrier properties, anti-static variants, chemical compatibility, transparency,

and heat-sealing capabilities, PVA films offer effective protection for

chemicals during transportation and storage. As the demand for safe and

reliable packing solutions in the chemical industry continues to grow, PVA

films are becoming increasingly popular as a trusted choice for chemical

packing materials.